January 22, 2025

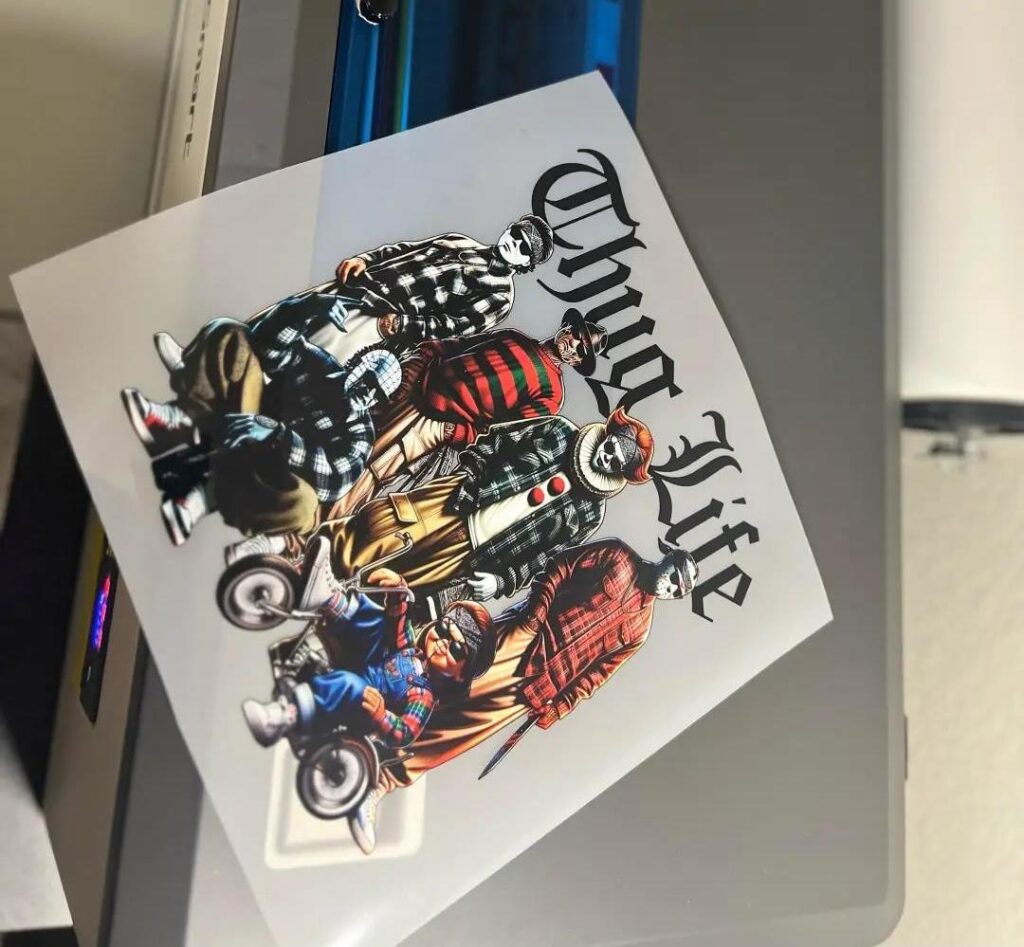

One of the most common prints

The pigment is first printed on paper by printing method to make transfer printing paper, and then the color is transferred to the fabric by high temperature.

Generally used for chemical fiber fabrics, characterized by bright colors, delicate layers, vivid patterns, and strong artistry, but the process is currently only applicable to a few synthetic fibers such as polyester.

The transfer printing process is simple, the investment is small, the production is flexible, and the market is relatively common.

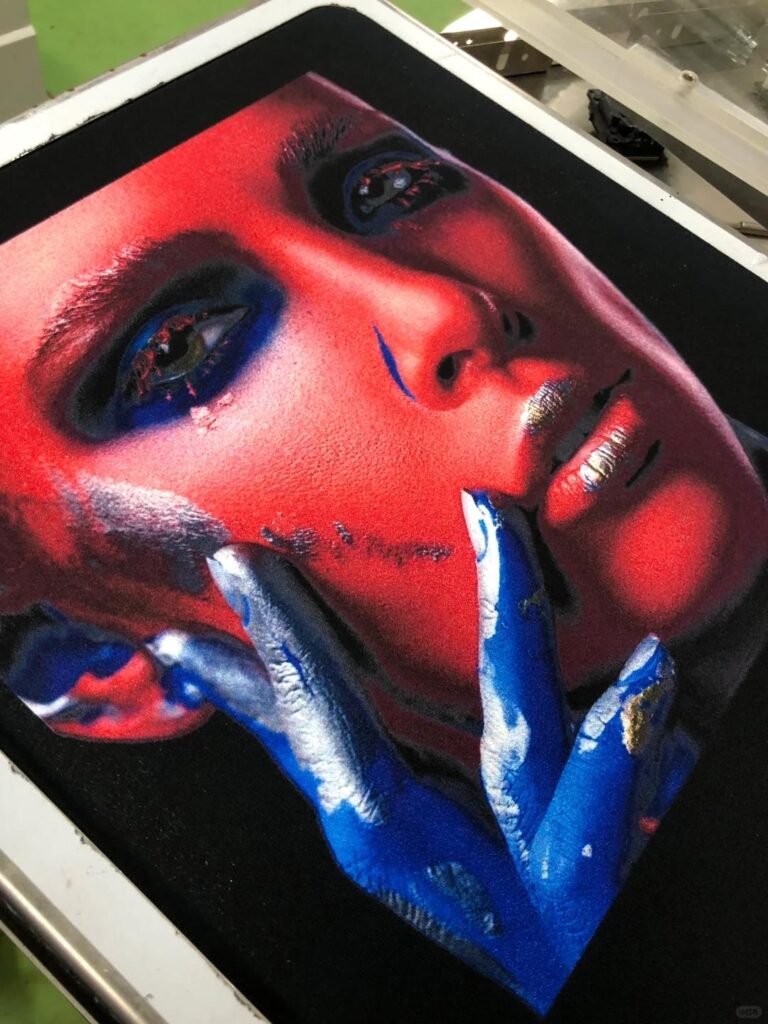

One of the most common prints

At present, it is mainly used in cotton, general hemp, silk and other woven and knitted fabrics or fabrics with higher components above.

Can also print a single drawing, can also print cloth.

Printed on the clothes feel is not strong, the coverage is weak, only suitable for printing on light colored fabrics. Because it does not affect the original texture of the fabric, it is also very breathable, suitable for large-area printing patterns, and the price is relatively cheap.

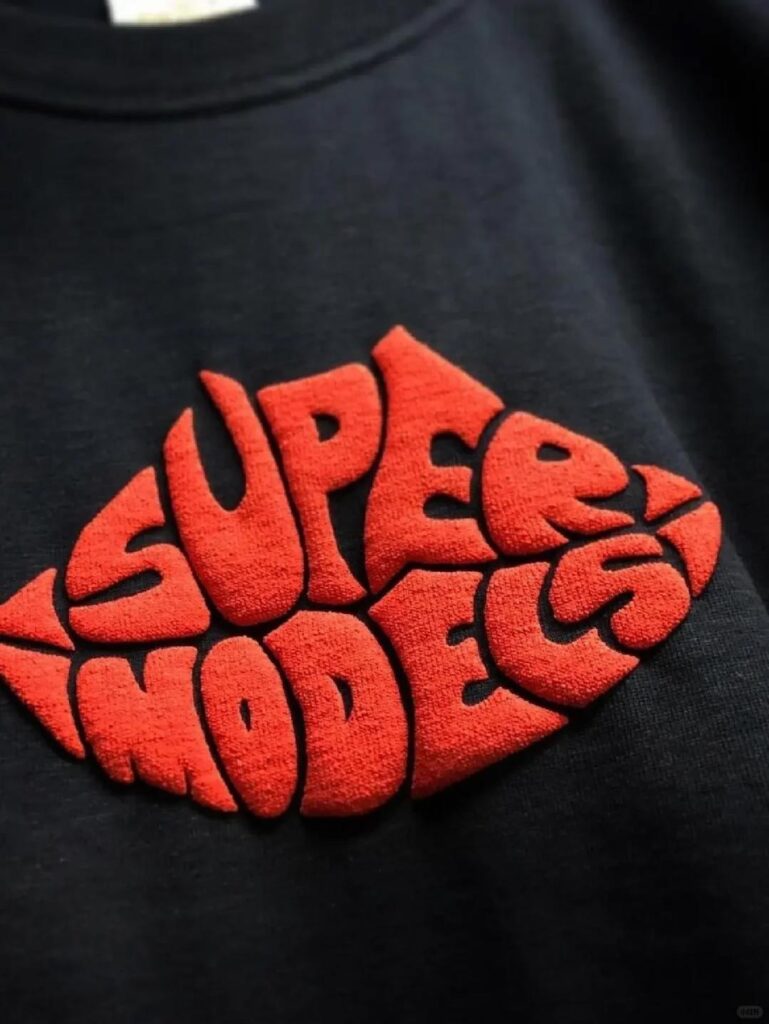

Good coverage and gloss and three-dimensional, but because it has hardness, it is not suitable for large pattern

Its effect is usually more prominent, which can make the clothing look more three-dimensional and rich sense of layer

Drawing printing is suitable for designs with high requirements for pattern fineness, especially in fabric softness and color performance, but it needs to be extra careful in the selection of fabrics and process control

It is a special printing technology, by printing blowing agent on the fabric and heating, so that the printed part of the three-dimensional effect, adding a sense of thickness and unique touch to the fabric.

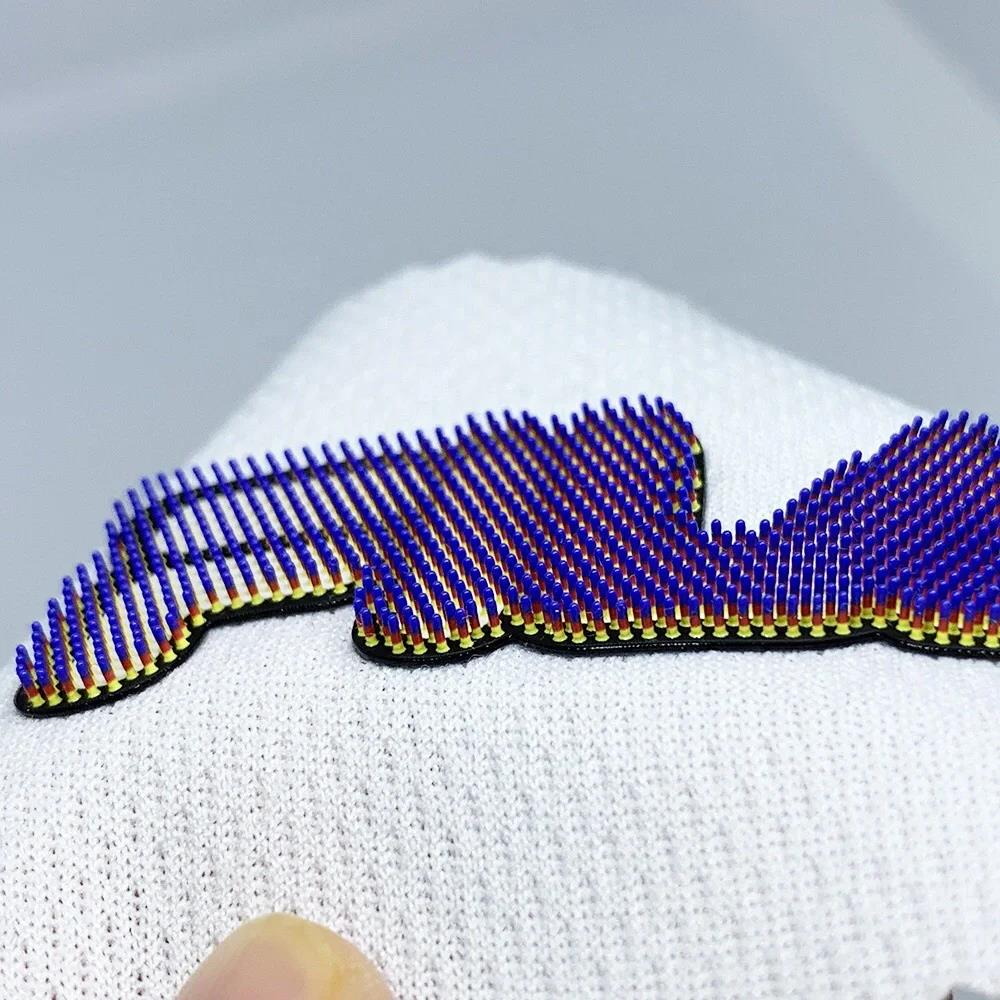

The height of the finished product can reach about 0.3CM, its top is bead-shaped, can do other colors on top, it seems to be topped with a bead, so it is also called planting beads.

Hot Stamping process is a technology that transfers metal film (usually gold or silver) to fabric, paper, plastic and other surfaces by hot pressing to form a metallic luster effect.

It is a process in which the printing paste containing special heat shrinkage, hardening and brittle components is printed directly on the T-shirt fabric through the screen plate and then dried to naturally form a special effect of texture cracks like the turtle back

Provide any printing process, no matter what your design is, we can present it perfectly for you.

To choose our factory is to choose quality, innovation and reliability!

Contact us today to start your creative journey together!